OUR SOLUTIONS

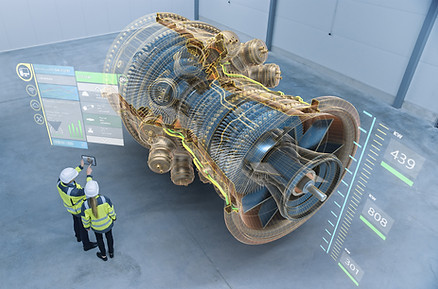

Digital Mockup

Fast digital mockup with collision check - even for very large structures

A Digital Mock-Up (DMU) is a concept and process in the field of product lifecycle management that uses digital 3D models of a product to virtually analyze and validate its design, functionality and assembly capability in the early development phase – without physical prototypes.

Purpose and benefits of DMU:

-

Virtual assembly testing – checking whether components fit together correctly (so-called "fitting checks")

-

Collision check – detection of potential collisions between components

-

Motion simulations – investigation of movement sequences and mechanisms

-

Dimension and tolerance analysis

-

Time and cost savings through fewer physical prototypes

-

Interdisciplinary collaboration between design, manufacturing, service and marketing

FastDMU from valexcon comes in right here:

Our solution enables lightning-fast visualization and navigation through complex product structures – even models with thousands of components. A powerful toolset for extracting, filtering, analyzing, and processing CAD data provides precisely the information users truly need.

FastDMU (Digital Mockup & Collision Check)

Your advantages:

-

Lightning-fast loading of even large models

-

Intuitive navigation in the context of selected configuration

-

Collision analysis directly in the 3D view

-

Support with design review

Whether for preparing design reviews, for engineering or for supporting change management:

FastDMU provides clarity – exactly where it is needed.

Processing and visualization

FastDMU enables powerful data processing as well as the loading and visualization of very large assemblies, which can consist of several thousands to millions of individual components. This can be, for example, a complete vehicle, a passenger aircraft, an entire production hall, or even a cruise ship, including all metadata and geometry. Furthermore, the loading and display of products in different configurations is possible, e.g. the simultaneous display of multiple vehicles with different configurations, such as left- and right-hand drive.

Filtering and navigation

FastDMU offers easy navigation and interaction with large product structures. Users can display metadata in various views: TreeView, ListView, PropertiesView, and BomView. Geometry contexts in CATIA are efficiently managed and visualized through data caching, an instance reference model, or selectable levels of detail. Functional data filtering is performed via the product configuration, e.g. via config handlers or milestones. Simple and more complex search functions such as build space or proximity searches are targeted, even combined with automatic setting of visual properties (color, transparency, visibility).

Geometric validation

For the geometric validation of your products, FastDMU offers automatic collision calculation (contact, intrusions, minimum distances, single or multiple collisions). This works for both fully configured products and unconfigured projects. Identified collisions are managed via a dedicated database. Display in CATIA is done via ClashViews and with the customer system (classification). The integration of FastDMU into CATIA enables combined work with visualization and native data – a true "design in context."

Data security

Your product data is secure in FastDMU. We offer secure data processing according to the latest standards, with transfer and management measures (ISSO) such as HTTPS, data encryption, and smart card authentication.

FastDMU consists of the following system components: